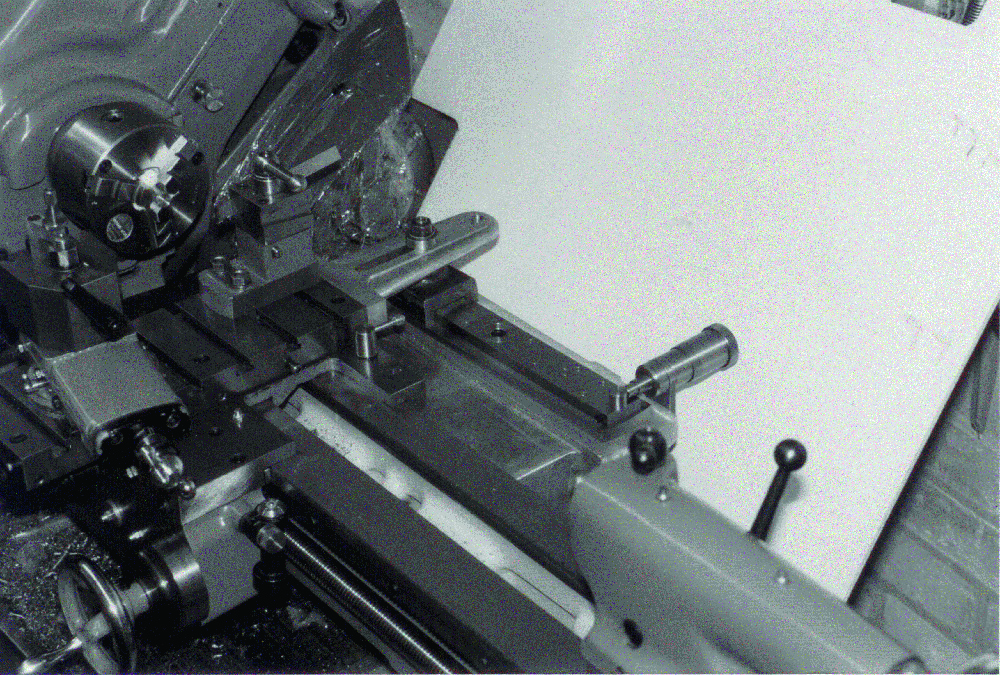

With a nominal 10" (250mm) working length, the Taper Turning Attachment Mk2 is conventional in so much as the design follows accepted practice. It does, however, have some features which we believe have not been generally available. The attachment bolts to the rear of the lathe bed. Myford supply their 7 Series lathes with holes already drilled and tapped to accept such an accessory but adaptation of other beds may be practical.

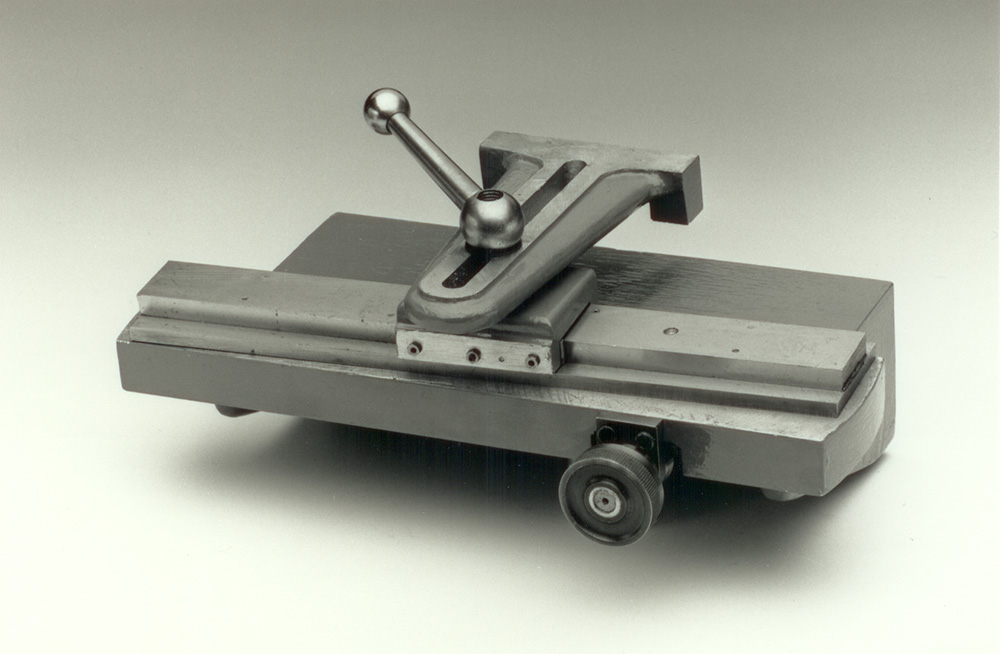

The slotted link is bolted to the rear of the cross-slide. Please note that this link does not stand proud of the cross-slide surface in any way, thus the whole of the boring table area is free for use at all times. Once the attachment has been fitted to the lathe, it is left permanently in situ, and the lathe can be made ready for taper turning in a very short space of time. All that is needed is to release the cross-slide feed screw, bring the top-slide into a suitable cutting position, clamp the slotted link to the guide bar using the ball handle and, apart from placing a suitable tool in the tool post, setting up is now complete.

For general taper work the guide bar is easily adjusted and clamped using the graduated scale. Accurate tapers, as required for say Morse taper or ER tooling, demand the exact position of the guide bar to be established. A precision setting micrometer, that enables quick and extremely accurate angular settings is detailed in the drawings. The design is equally accurate for both male and female tapers. The kit includes aluminium castings for the main bracket and slotted link and a gunmetal casting for the slide. All other material, together with fasteners, drawings and instructions are provided. The accessory costs well under half that of a conventional, off-the-shelf product, not having the advantages of this new design.