Filing rests may strike you as old fashioned - from the era when none but the wealthy had milling machines? However, a good deal of the milling required in the small workshop consists of shaping hexagons, squares, and simple forms of cams on cylindrical work, and for this purpose, there is much to be said for a filing rest, which can be rigged in the lathe in as little time as it takes to change a tool and requires no more in the way of additional equipment than a couple of ordinary files. It has the same advantage as an overhead-driven milling fixture or even a Quick-Step Mill in enabling work to be operated on in situ without removing it from the lathe chuck or between centres.

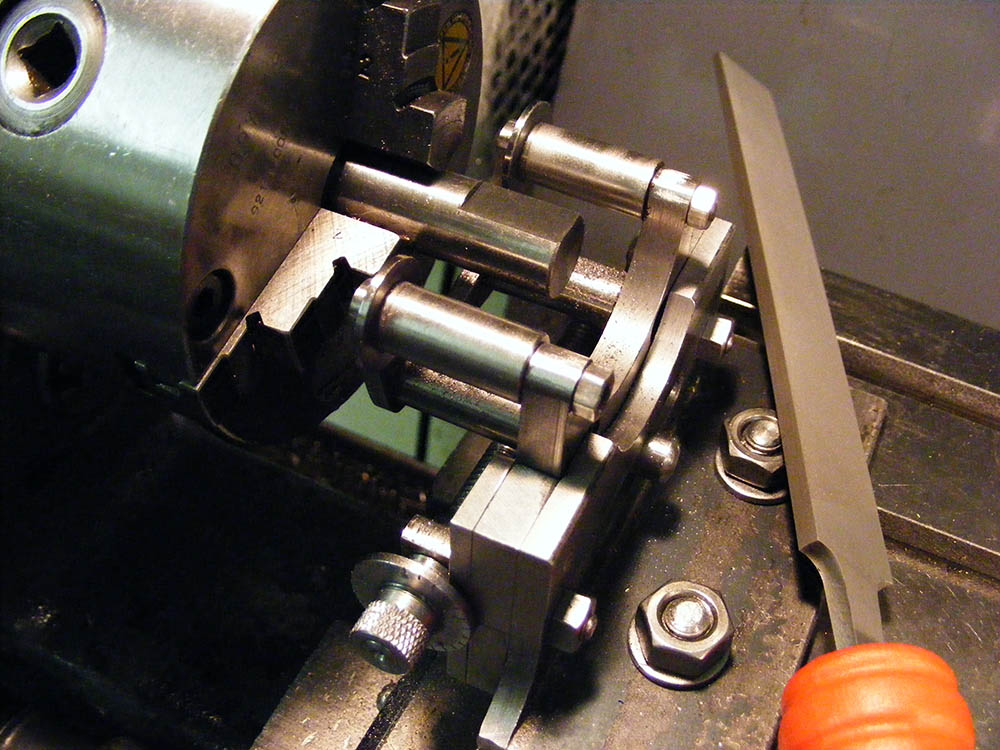

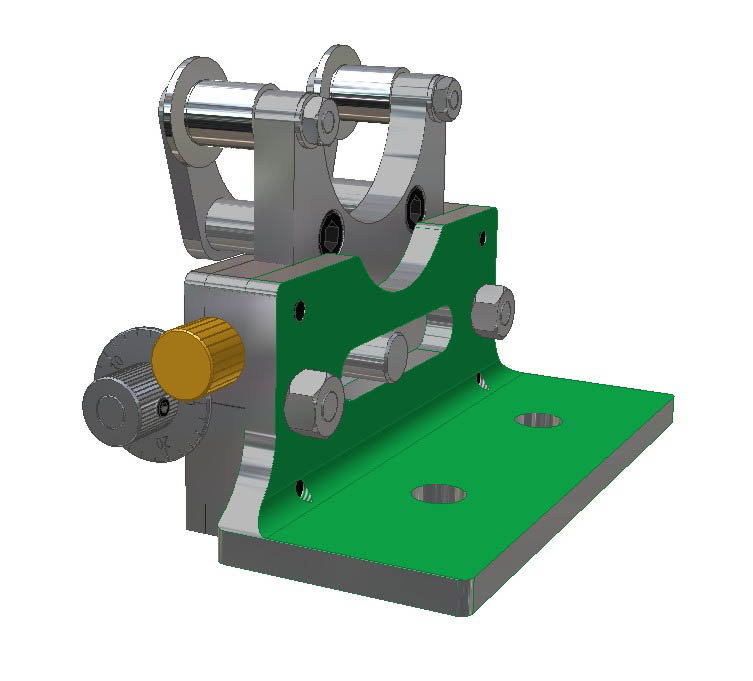

This design, by Edgar Westbury, is thoroughly well conceived. Whilst many filing rests mount onto the bed of the lathe, by far the best location is on the cross slide where the saddle can be easily traversed to set the file's safe edge accurately along the job. The conventional screw-jack approach used for bed mounted rests cannot however be shoehorned into the space over the cross slide but this design, with its unique scissor lift action, can be set with perfect precision to within 0.001".

Hexagons and squares up to 1 1/8" AF can be quickly and accurately "milled" on boiler fittings and fasteners before parting off. The filing rest can also be used for the production of D-bits and single lip milling cutters, which are sometimes a little difficult to measure up properly if they happen to be tapered or otherwise varied in diameter. Also, in concert with a Headstock Dividing Attachment, tangential cams for model engines will become significantly less stressful!

This item can be fitted to the cross slide of virtually any lathe of around 3 1/4" centre height and upwards. The kit includes all necessary materials together drawings and Westbury's notes for both construction and use.