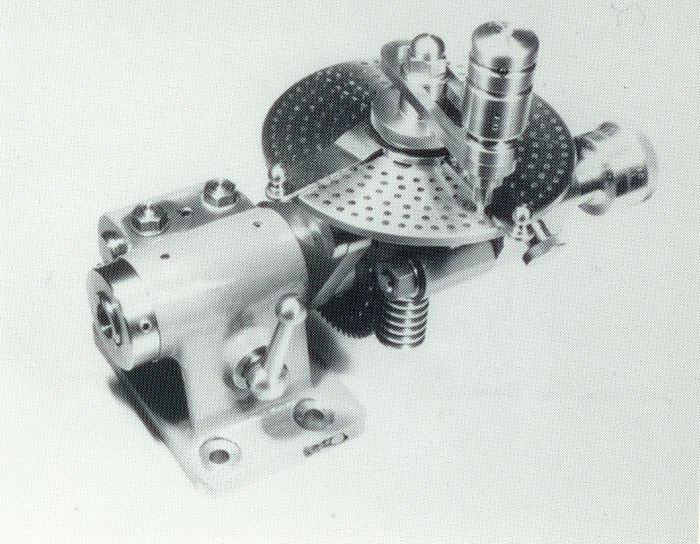

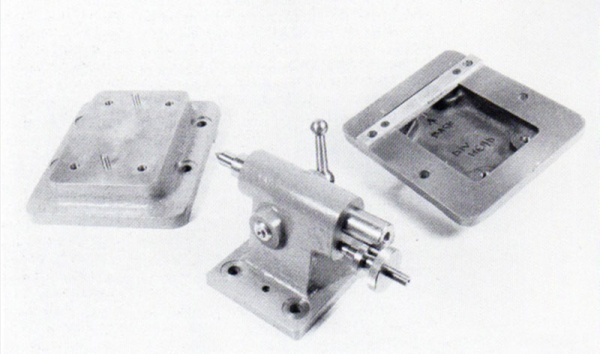

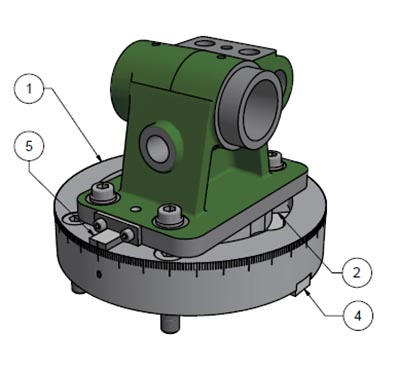

| Versatile Dividing Head & Accessories

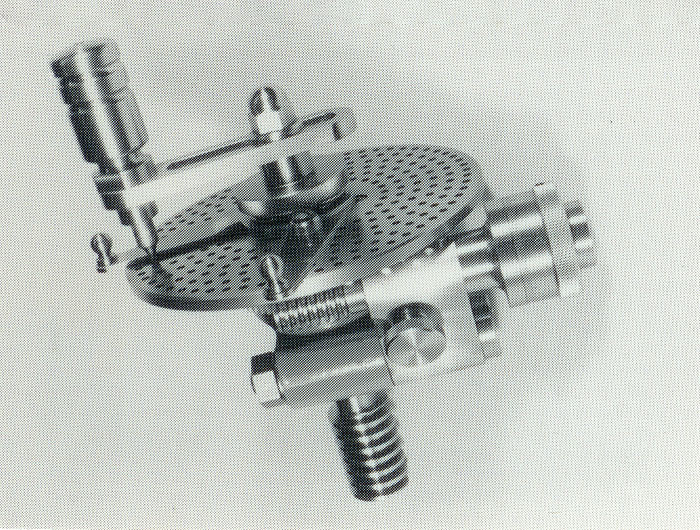

Simple Indexing is by means of a spring loaded plunger engaging any of the 24 holes in the face of the main wheel. Squares, hexagons, keyway cutting and tap fluting are conveniently done by this method. Conventional Dividing is by means of the usual worm and division plate, which now replaces the spring loaded plunger. Both this and the plunger are mounted on a banjo which can be swung around the main casting to the most convenient operating position. The three division plates will allow most divisions used, including angular spacing, to be obtained. Prime numbers, or indeed any possible division outside the range of the three plates, are indexed by means of the “Micro-Attachment” giving capabilities down to 0.001° (3.6 seconds)! Thus a second worm and wheel are attached under the division plate, allowing calculated manual rotation of the division plate, by means of the calibrated knob at the end of the worm shaft. This rotation or correction is done at each step of the dividing. Please note that the VDH kits arrive WITH our latest drawings but WITHOUT build notes. You will therefore need a copy of "Workshop Techniques" by G H Thomas; 11 chapters of which include all necessary information to both build and use the remarkable VDH.

|

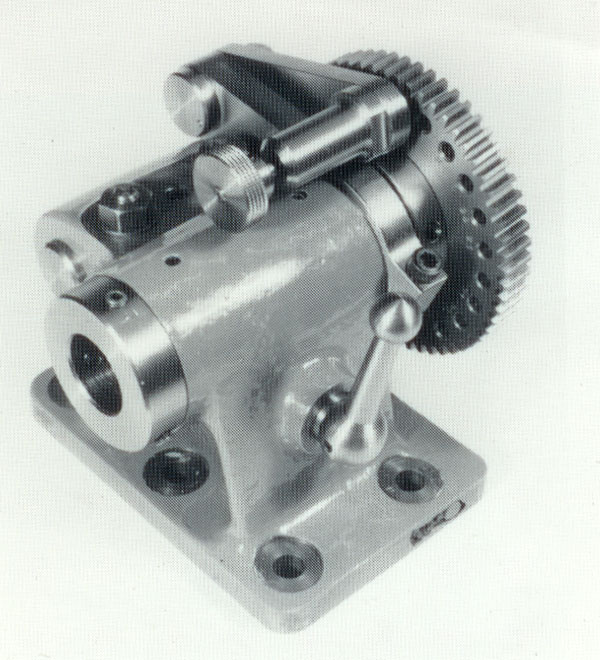

Commercial dividing heads often find disfavour among Model Engineers, because they do not always fulfill the varied needs of the smaller workshops. In this design, consideration has been given not only to the wide range of possible uses of the Versatile Dividing Head (VDH for short) but also to the simplification of construction. In this context it may be mentioned that this dividing head generates its own division plates to a very high order of accuracy. The dimensions are such that all components are machinable on a lathe of minimum 3 ½" centre height.

Commercial dividing heads often find disfavour among Model Engineers, because they do not always fulfill the varied needs of the smaller workshops. In this design, consideration has been given not only to the wide range of possible uses of the Versatile Dividing Head (VDH for short) but also to the simplification of construction. In this context it may be mentioned that this dividing head generates its own division plates to a very high order of accuracy. The dimensions are such that all components are machinable on a lathe of minimum 3 ½" centre height.