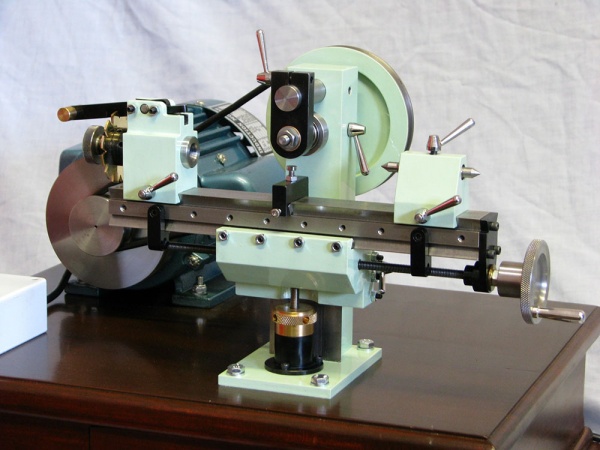

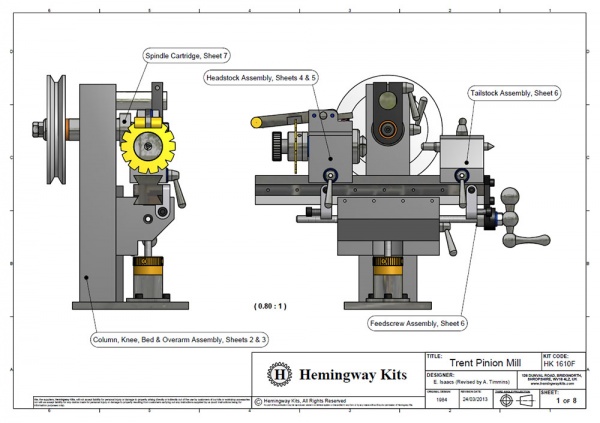

| Trent Pinion MillAccurate pinion cutting has always presented a problem to clock makers without access to sophisticated machinery. Particularly for the craftsman who requires small numbers of perhaps widely differing sizes. Now, perhaps for the first time, a machine is available in kit form to overcome the problems of pinion cutting for the clock and instrument maker. Designed by Elliot Isaacs and further developed by Alan Timmins, the Trent Pinion Mill design includes substantial castings and dovetailed work slides to both ease manufacture and improve accuracy. Basically a miniature milling machine with integral dividing head, the Trent provides maximum rigidity both in cutter support and work holding. The pinion or small wheel being cut (up to Ø2") is held in collets or between centres and is indexed by a notched plate with provision for backlash adjustment. Pinions can be quickly and accurately cut in even the toughest materials, with or without coolant. The design accepts your cutters up to Ø35mm on a standard Ø7mm bore. Travel in the X, Y and Z planes are 4", 3/8" and 2" respectively. The completed mill weighs 8.5kg (19lbs) and stands 8" tall by 12" wide by 6" deep. Please note that to complete the dovetails on the bed and table you will need access to a mill with at least 9" of X-axis travel.

| ||||||||