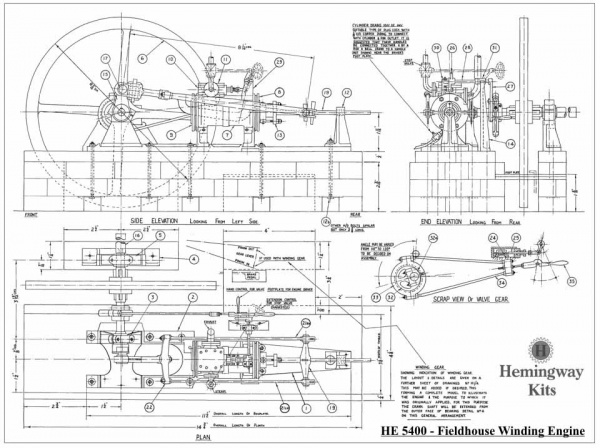

| The Fieldhouse Winding Engine

"Business is rising, increasing, flourishing. I have just been on my knees to thank the Lord!".

The Fieldhouse Engine is of an unusual early design and was preserved in 1952 at the Tolson Memorial Museum. Geoffrey King, a professional engineer and member of the Newcomen Society designed and developed this magnificent 1/12th scale working replica in 1955. Bore x stroke for the engine is Ø7/8" x 2" and the flywheel has a diameter of Ø8 5/16". The winding drum was designed to run at around 10rpm, pulling rope and trucks at around 1 mph up the slope. A band brake then allowed gravity to return the empty trucks safely - there was no means of reversing the drum. The complete model (engine along with winding gear) sits on a plinth of around 15" x 15" and is a superb piece of machinery to watch and enjoy! The Fieldhouse Winding Engine in Action

|

Having lead a life of leisure for 50 years, Edward Brooke, a Wesleyan preacher and son of a wealthy Yorkshire mill owner, speculatively acquired a small tract of land north east of Huddersfield. Having bored for coal he found "fireclay", a refractory material much in demand throughout the developing world. In 1850 he set up the Fieldhouse Fireclay Works to capitalise on this find - he was soon able to report that:

Having lead a life of leisure for 50 years, Edward Brooke, a Wesleyan preacher and son of a wealthy Yorkshire mill owner, speculatively acquired a small tract of land north east of Huddersfield. Having bored for coal he found "fireclay", a refractory material much in demand throughout the developing world. In 1850 he set up the Fieldhouse Fireclay Works to capitalise on this find - he was soon able to report that: As much of the siding system at Fieldhouse was laid on a gradient, a method of rope haulage was adopted to move the loaded rail wagons from the loading and weighing point, in the heart of the works, up to the main rail tracks.

As much of the siding system at Fieldhouse was laid on a gradient, a method of rope haulage was adopted to move the loaded rail wagons from the loading and weighing point, in the heart of the works, up to the main rail tracks.