| B Hick & Son - Crank Overhead Engine

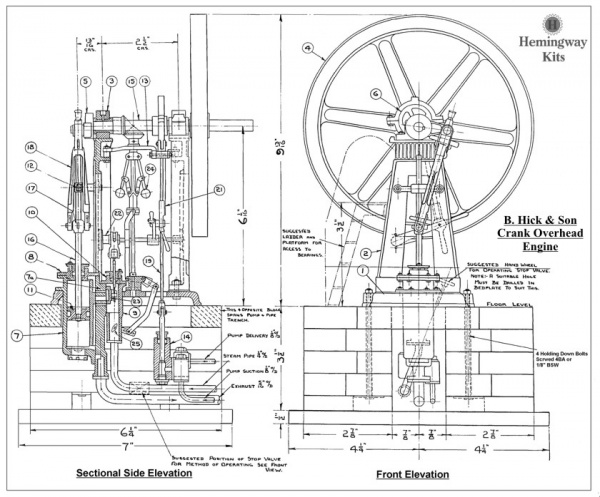

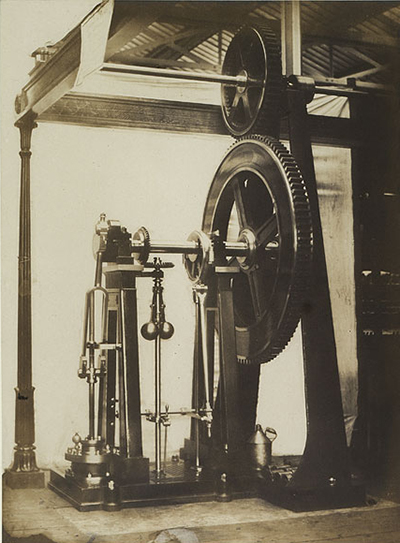

Continuing his father's great leap, John Hick MP represented Bolton in Parliament from 1868 - 1880. At home (Mytton Hall) however, he retreated regularly to his full steam driven workshop where Mrs. Hick stoked the vertical boiler! This particular 10nhp engine was shown by the company at the Great Exhibition in 1851, alongside their diminutive Oscillating engine. Geoffrey King, a professional Engineer and member of the Newcomen Society, detailed this 1" to 1' replica in 1956 from the original Hick drawing set. The vertical layout made this engine particularly suitable for driving "manufactory" line shafting, with the cylinder, valve chest and feed pump installed in a pit below. Where more that 10nhp was required, gangs of engines could be coupled together and managed by a single boiler and "engineer". Complete with its 7" x 8½" plinth the model stands almost 14" tall propelling a Ø7½" flywheel. With a bore x stroke of ¾" x 1 7/8", the engine has a double acting slide valve, an eccentric driven feed pump and a Watts type governor, driven directly from the crank with bevel gears. An imposing runner, the 'Crank Overhead' shows a great deal of movement when underway. The Hick & Son Crank Overhead in Action

| ||||||||

Situated in the centre of Britain's cotton and coal industries, Benjamin Hick grew his Bolton foundry business to employ over 400 men before his death in 1842. His son John then partnered with William Hargreaves in 1845 to form Hick, Hargreaves & Co, supplying a vast range of stationary and locomotive steam engines, boilers, water wheels and mill gearing to customers at home and overseas (including India, Russia, Spain, South America, China, and Japan). In 1864, they were also responsible for the introduction of the highly efficient American Corliss valve gear into the UK.

Situated in the centre of Britain's cotton and coal industries, Benjamin Hick grew his Bolton foundry business to employ over 400 men before his death in 1842. His son John then partnered with William Hargreaves in 1845 to form Hick, Hargreaves & Co, supplying a vast range of stationary and locomotive steam engines, boilers, water wheels and mill gearing to customers at home and overseas (including India, Russia, Spain, South America, China, and Japan). In 1864, they were also responsible for the introduction of the highly efficient American Corliss valve gear into the UK.